Driving Solutions

Since 1959, ABBA Roller has been the world-leading provider of Critical-To-Function, (CTF) high-precision, rotary components.

Our sole mission is to supply your company with the highest precision & tightest tolerances available for complete newly manufactured and reconditioned Rubber & Chrome Rollers.

Through our unmatched rubber chemistry and engineering capabilities, we leverage custom formulation designs to meet critical requirements. ABBA Roller provides in-house compounding of all elastomeric materials that are batch tested for quality & consistency in our Chemistry Laboratory.

We are critical, precise, period.

Driving Solutions

Since 1959, ABBA Roller has been the world-leading provider of Critical-To-Function, (CTF) high-precision, rotary components.

Our sole mission is to supply your company with the highest precision & tightest tolerances available for complete newly manufactured and reconditioned Rubber & Chrome Rollers.

Through our unmatched rubber chemistry and engineering capabilities, we leverage custom formulation designs to meet critical requirements. ABBA Roller provides in-house compounding of all elastomeric materials that are batch tested for quality & consistency in our Chemistry Laboratory.

We are critical, precise, period.

CRITICAL-TO-FUNCTION Engineering

Solutions

Fully integrated & staffed precision machining operation capable of producing complex roller core body designs such as Dual-Shell, Spiral Baffle Extrusion Line Chill, and Heat Transfer Rolls.

- All complete roller fabrications, re-stubs, core body and journal repairs are performed internally on our proprietary ABBA Roller engineered equipment.

Engineering

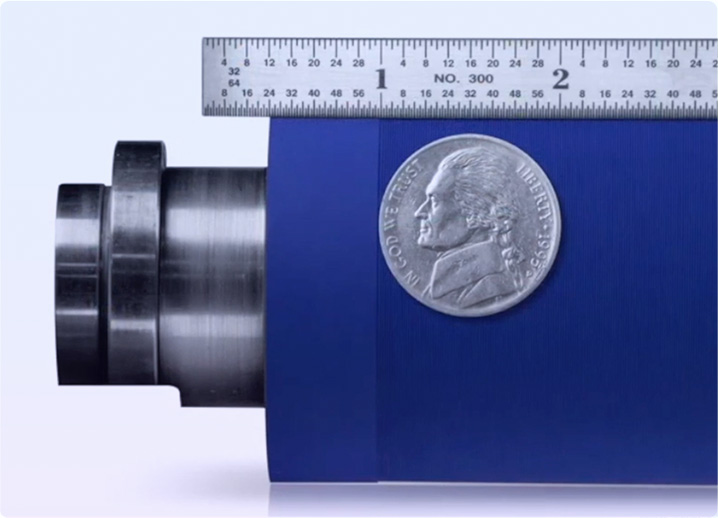

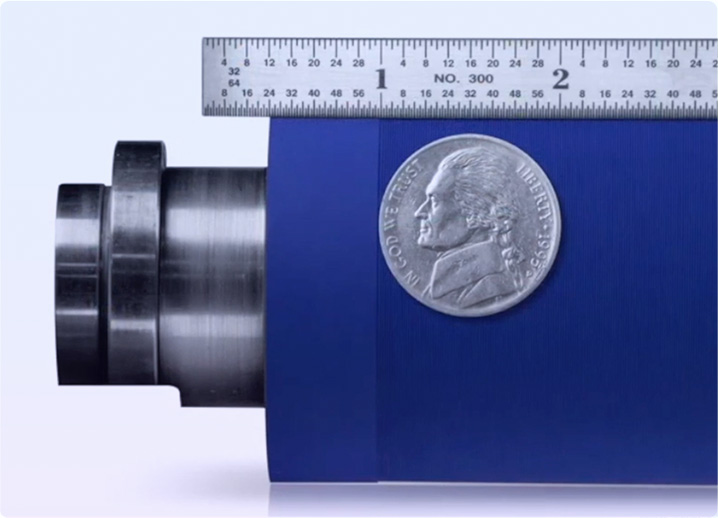

- ABBA Technicians utilizing CNC Cylindrical Roll Grinders produce precision roller diameter and roller cylindricity tolerances to 0.0003″ and hold roller total indicated run-outs to 0.0002”.

- Incoming & outgoing inspection areas equipped with our proprietary ABBA Roller Engineering designed non-contact laser mapping system for complete scientific roller tolerance verification.

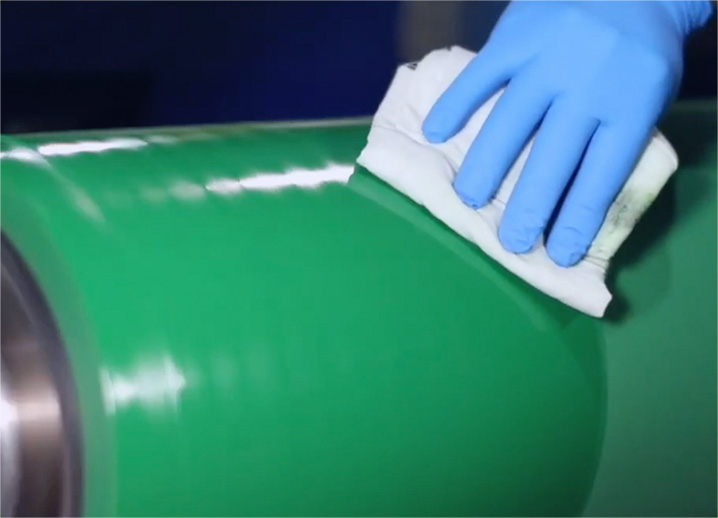

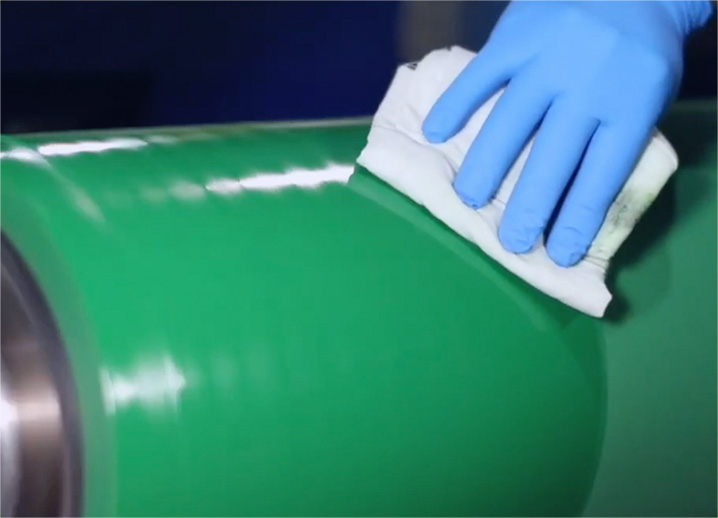

Recover & Repair

- We have in excess of 2,000 proprietary rubber formulations. All our roll covering formulations are milled in-house.

- Each rubber material is batch tested for consistency in our on-site Rubber Chemistry Laboratory.

CRITICAL-TO-FUNCTION Engineering

Solutions

Fully integrated & staffed precision machining operation capable of producing complex roller core body designs such as Dual-Shell, Spiral Baffle Extrusion Line Chill, and Heat Transfer Rolls.

All complete roller fabrications, re-stubs, core body, and journal repairs are performed internally our proprietary engineered equipment.

Engineering

- CNC Cylindrical Roll Grinders are capable of precision diameter roll tolerances of 0.0003″.

- Incoming & outgoing inspection areas equipped with our proprietary ABBA Roller Engineering designed non-contact laser mapping system for complete scientific roller tolerance verification.

Recover & Repair

- Experienced high-precision roll grinding technicians can regrind previously used rollers in bearings to the same extremely tight T.I.R., cylindricity, and roller profile tolerance specifications all at considerable savings to the end-user.

- Each rubber material is batch tested for consistency in our on-site Rubber Chemistry Laboratory.